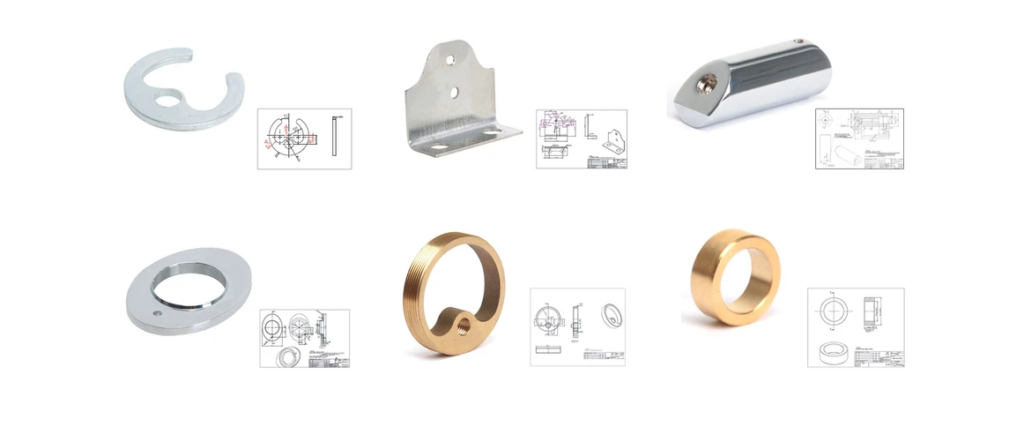

Tiroflx is well-positioned to provide exceptional service and offers high-quality precision parts in a variety of metal processing technologies suitable for our customers’ specific applications. Our goal is to satisfy our customers’ requirements or exceed them. With our highly-skilled craftsmen, quality control team, and various mechanical testing laboratories we employ, our array of available materials in the different manufacturing technologies gives our customers great value. We work according to drawing–

With Sheet Metal Fabrication, Custom Metal Stamping, CNC machining parts, Metal Casting services, and more-Tiroflx is a full-service provider of manufacturing and supply chain management.

Quality Control

Ordering complex shaped parts with tight tolerance requires extra attention.

Our quality control procedure contains:

Incoming inspection for the raw material, in-process inspection, after processing inspection, before parts undergo surface treatment or any surface finish is applied. Another inspection is done when parts are finished- to allow us final dimensions’ verification and visual inspection before shipment.

This methodology ensures that parts are following their specs and drawings, enables on-time shipment, and saves money by preventing disqualification of large finished batches.

Measurement devices: Precision CMM (3D coordinate measuring machine), 2.5D projector; Closed-loop QC system; Third-party inspection available if required;

Packing: Paper, EPE Foam, PE bag, polybag, pp bag for inside; Carton boxes, Pallets, Wooden boxes for outside; Or as customer required;

Surface Finish: High polish, brush, sandblast, anodization, plating, powder coat; Lacquer painting, Silkscreen, Pad printing; Laser engraving;

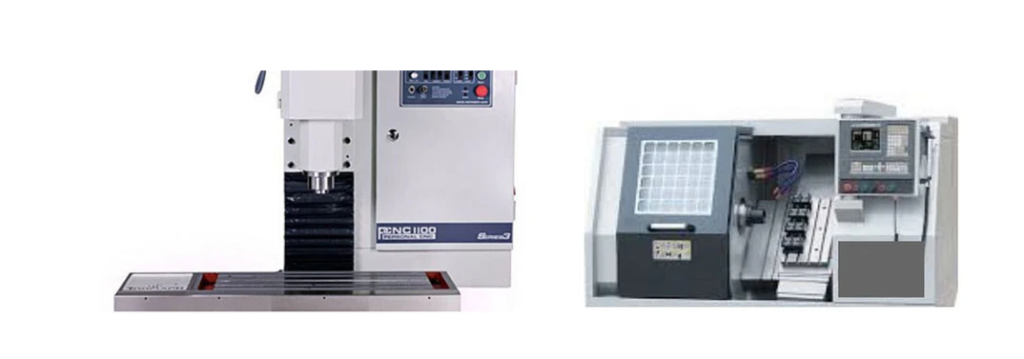

CNC Machining Services

CNC Machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers, and grinders. There are many advantages to using CNC Machining. The process is more precise than manual machining and can be repeated in the same manner over and over again. CNC Machining is used in the production of many complex three-dimensional shapes. It is because of these qualities that CNC Machining is used in jobs that need a high level of precision or very repetitive tasks

Turning

CNC turning produces parts by “turning” rods material and feeding a cutting tool into the turning material. On a lathe, the material to be cut rotates while a cutter is fed into the rotating workpiece. The cutter can be fed at a variety of angles and many tool shapes can be used. CNC turning provides an economical way to make parts that are commonly symmetrical about an axis of revolution.