Home » FAQ

FAQ

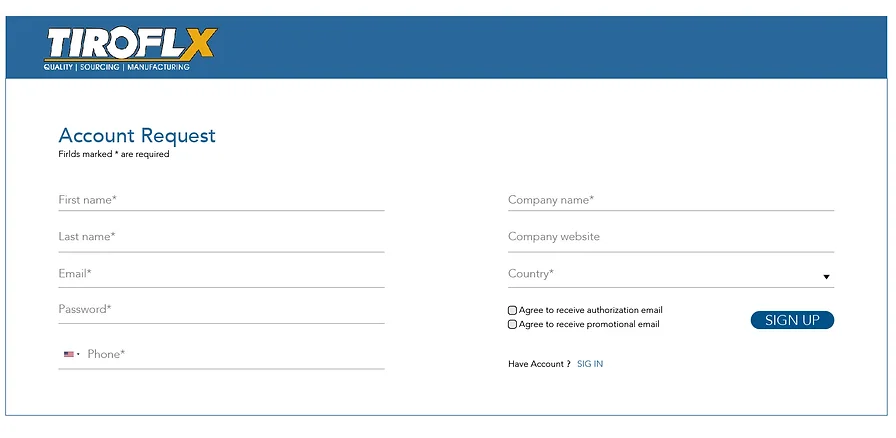

- Go to https://sourcing.tiroflx.com/login/

- In the top menu go to Login

- Register with your email.

- You’ll be asked to choose a password. Click Save.

- You’ll get an email to confirm your registration.

- You’re all set!.

Find our best seller products on the Best Sellers Accessories page on our website. Right now, the best-selling items go from phone holders to hand sanitizers, so the list varies greatly from time to time. Check the page regularly so you can find the most popular items to source.

At Tiroflx we are always on the search for the latest trends. That’s why we frequent all major trade shows all over China. You can see our latest findings in our New products page. Also, make sure to check our blog for our monthly updates.

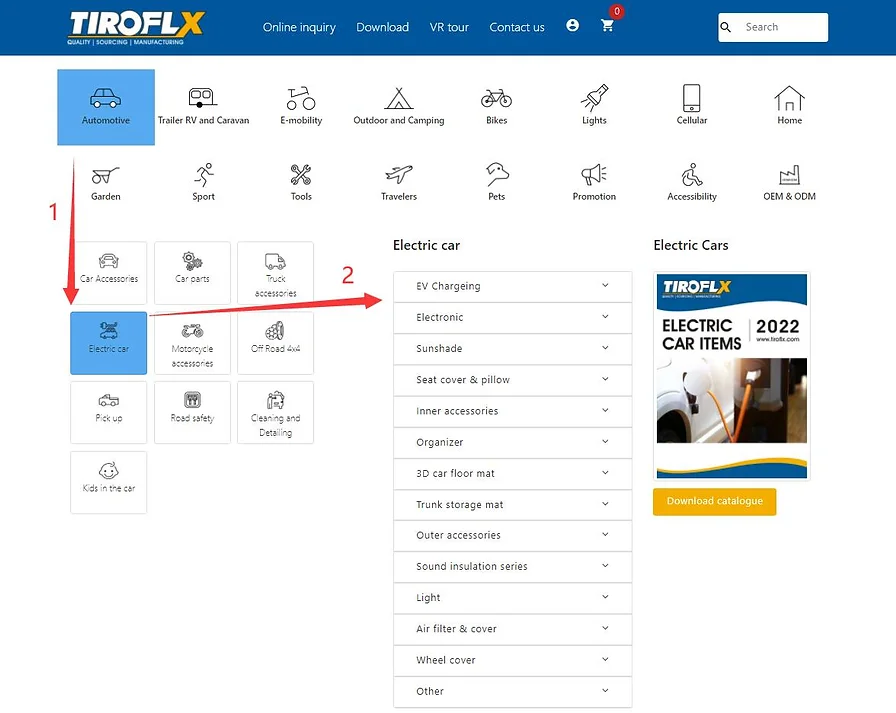

- To place an inquiry, you need to register as a customer. Look

- here for the instructions

- In our homepage, Online Inquiry.

- You will get to our Online Interactive Web Catalogue. There you can browse the categories until you find the product you want.

- Once on the product you want, just click on Ask an Inquiry.

- The product will be placed in your shopping cart. So you can continue browsing and adding products.

- Once you finished browsing all the products you want to inquiry about, just go to the shopping cart and select the product from your list.

- In the shopping cart, you’ll see the product picture, the MOQ (Minimum Order Quantity), a space to set the quantity of the product you want to ask for. Select the product you want to ask for and send inquiry.

- Once finished, you’ll get a confirmation message.

- According to your requirements, we will send you the best price offer for the product and more product information. If needed, we may ask for further requirements in another email.

You can search by looking at the categories or using the Search box. If the product you want is not in our catalogue, contact us with your requirement and we will find the best option with the best quality and the best price.

If the product you want to produce is not in our catalogue, no problem:

1. Contact us. Show us a drawing or a picture of a similar item. You can send us an engineering design or just a sketch.

2. We will contact you back for more details. We then will suggest the best materials for the product from the top sheet metal, die casting, and plastic factories in China.

China was the first country impacted by COVID-19 and one of the most hit with a drop in business. Yet companies continued their work, and factories continued as much as possible.

While the outbreak of the pandemic affected business activities, we strive to keep business as usual while taking the required precautions. Trade shows are back again and at Tiroflx we are attending to them all over China with the goal of finding the latest trends and products.

Trading companies don’t manufacture or retail products. Instead, they source from selected factories according to the requirements of their clients. They connect buyers with the right manufacturers for the products. At Tiroflx, we select and work with over 1500 factories carefully selected by their processes and quality.

Trading companies have the advantage that they can offer an array of products, since they are not limited by what one factory can produce.

Trading companies don’t directly manufacture products, but connect buyers with the right manufacturers. The main advantage of working with a trading company is that they can choose the best option among an array of manufacturers.

Working directly with a manufacturer can be useful if you have the expertise and the market knowledge to choose the best factory in China for your product. Usually Chinese manufacturers are highly specialized in one product type or one manufacturing process. For instance, a company that manufactures golf shoes would not make golf bags.

China has emerged as the top manufacturer for a majority of brands. Why do so many companies choose to produce in China? Here are 4 reasons:

- Low cost – according to studies, manufacturing in China can help reduce costs from 30% to 80%.

- Strategic location – China is close to growing markets like India and South Korea.

- Advanced Supply Chain Management – Chinese suppliers have updated their supply chain management processes with the latest technologies, raising their standards to international levels.

- Access to state-of-the-art technology – due to the potential of their manufacturing in the global market, China is developing its technology with new AI and electronic products.

We work under the AQL – (Acceptable Quality Level) quality control concept.

IT refers to the minimum level of faults that are acceptable in a sample of a manufactured product.

For an entire batch to be accepted, the number of faults need to be lower than the AQL. If it is higher, the entire batch is rejected.

We carry on quality control during and after production by our in-house QC team.

We combine the in-factory control with global laboratory tests to achieve compliance with the strictest EU regulations.

You can learn more about our process here

Today — an integrated, sustainable, quality management program with clearly focused networks is a decisive competitive advantage. At Tiroflx, we conceive your quality requirements to precisely match your business processes and offer you comprehensive support — ranging from the creation of a zero-defects culture to the development of a value-added orientation. Here, Tiroflxs’ experienced experts always examine which quality methods are most efficient for your particular product and how requirements can be optimally applied to your needs.

We check the factories samples for quality and also for price. Then we conduct a thorough factory audit, which includes checking:

- Factory profile

- Organization/ process

- Materials and quality assurance system

- Production capacity

- The state of the facilities and machinery

The audit includes pictures of facilities, materials, and machinery. We have a scoring system and approve the audit only to factories that have fulfilled 80% of the requirements.

After the factory audit, we conduct background checks, both financial and legal liabilities. We confirm the work after a thorough check if everything is okay.

We create a specific contract for each order and factory. This includes all the terms and specifications for the order. Once it is in production, we will control that the factory fulfills all the teams in the contract.

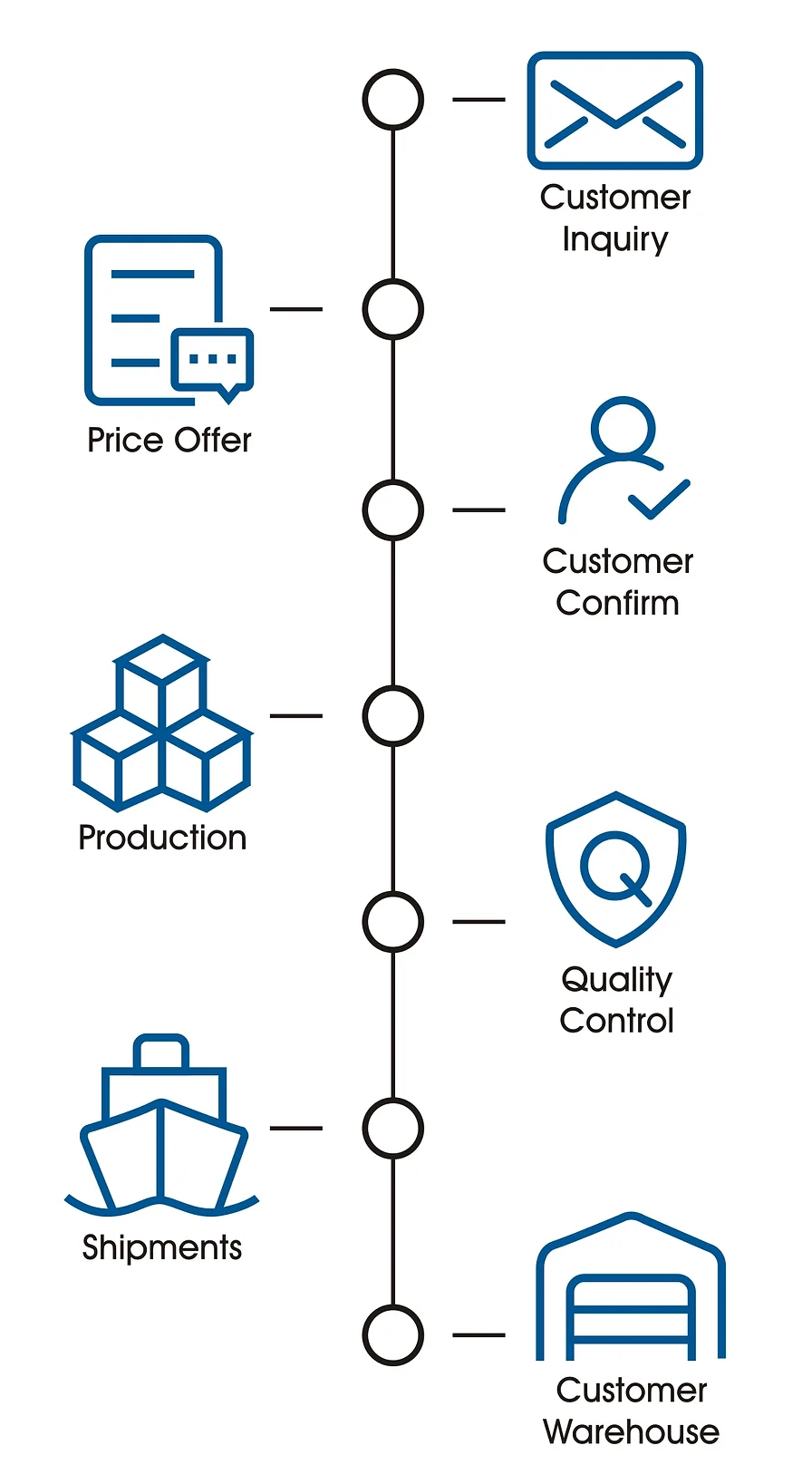

Our Standard Operation Process

We are fully ERP computerized. All the process is conducted within the management system.

Step #1

Customer inquiry – this can happen via email, via our interactive catalogue or our

showroom. The customer can also send us photos, samples or technical drawings of the product they want to manufacture.

Step #2

Price offer (now inside the ERP)

1. In-Sourcing items: we look in our database of factories for the requested items, selecting the ones with the best price and quality. We then give the customer a price quote based on their specifications.

2. If the customer intends to send an item to manufacture, usually they send us a technical drawing or a sample of what they want to produce. Our engineers find which of our 1500 factories is the right fit to make the mold and produce the item.

Step #3

The order process (inside the ERP)

After the client confirms the contract, we make the order to the factory. Each work order confirms the price and includes a complete detailed contract with the factory with the items’ specifications, packing, delivery time, and the details.

While the order is in production, we design the artwork, instruction manuals, and packaging if required.

Step #4

Quality control (AQL)

We conduct quality controls during and after production. Based on the contract and standards required for the product, we check the items for quality and compliance. Items that are produced for the European market, are also checked by external laboratories for specific material requirements tests.

Final steps

Shipments Warehouse

If everything is all right, confirmed by our QC and QA team, we confirm the factory can send the goods to the warehouse for a final check and arrange for shipment. Since customers can place different orders from different factories, we stock them in our warehouse, consolidating the container for the shipment. We check a final time before loading to prevent possible last-minute or overlooked faults.

The Business Social Compliance Initiative (BSCI) is a leading supply chain management system.

It supports companies with the goal to drive social compliance and improvements within the factories and farms in their global supply chains.